Fundamentals of Design

Course Features

Course Details

Course Overview

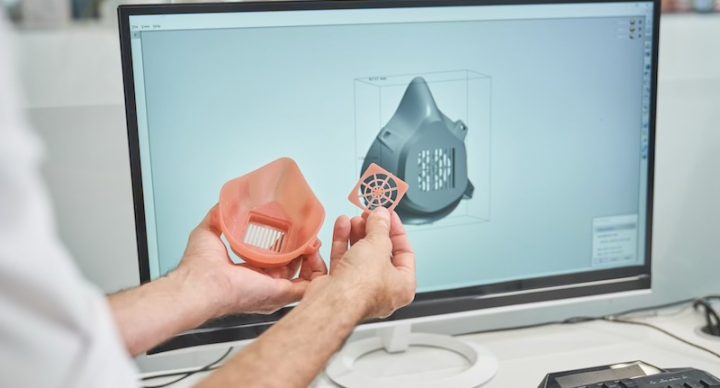

Fundamentals of Design is a year long course focused on introducing students to the technical art of 3D printing while growing the mind into the 3D design process, beginning with design ideas and developing them into reality. The 3D printing process is revolutionizing the way prints are converted seamlessly and accurately into functional objects. In this course, students will learn a vast scope of knowledge about 3D printing, starting with an inclusive overview regarding the innovative technology to the implementation of 3D processes used to create 3D models.

Sample Lesson - Introduction

This course was developed by the International Academy of Science.

Learn More

This course was developed by the International Academy of Science.

Learn More

Scope and Sequence

Unit 1: Overview of 3D Printing In this unit, the student will be able to identify six technology 3D printing processes, material groups and different polymer forms in 3D printing, as well as common thermoplastic, thermoset, and metal processes. In addition, they will learn how to recognize five types of form. Unit 2: Material Extrusion – Fused Filament Fabrication In this unit, the student will learn different components of a Fused Filament Fabrication (FFF) process, including names and parts on the printer, the parameter adjustments to achieve accuracy, causes and cures of warping, characteristics to achieve solid layer adhesion and support structures, as well as common infill geometries and percentages. The unit also covers strategies to improve dimensional accuracy, matching materials and characteristics, along with identifying seven post processing methods, benefits, limitations, characteristics and differences between industrial and desktop printing. A student will then become familiar with common applications, three new FFF process developments, and understand how designers use principles and elements of design to create compelling compositions known as Form and Function. Unit 3: VAT Polymerization – SLA/DLP In this unit, the student will learn the characteristics of the 3D VAT Polymerization Technologies, including the Stereolithography (SLA) process, the Direct Light Processing (DLP) and how it’s used to create 3D prints, as well as comparing fundamental differences between the SLA and DLP processes. The unit also covers the characteristics of VAT Polymerization, adjusting printing parameters, the advantages and disadvantages of two common Vat Polymerization configurations; bottom-up and top-down. In addition, how support structure is utilized, specific methods of managing dimensional accuracy, material/performance characteristics, common post processing techniques, benefits/limitations, differences between industrial and desktop units, along with identifying four different applications. A student will then become familiar with aspects of a new process called “Continuous Light Production” and identify different types of Lines as well as the characteristics of each kind. Unit 4: Powder Bed Fusion – SLS In this unit, a student will learn various aspects of the Selective Laser Sintering (SLS) process, including printer characteristics and parameters, how a powder bin is packed for efficiency, layer adhesion, shrinkage/warpage, characteristics/parameters of PA 12 nylon, post processing, benefits/limitations, three common applications, and three new developments in SLS printing. In addition, aspects of “Multi Jet Fusion” printing and a Plane. Unit 5: Material Jetting – DOD In this unit, a student will learn the aspects of the Material Jetting (MJ) process, including characteristics, Drop On Demand, printing parameters, support structures, the differences between matte and glossy finishes, dimensional accuracy, materials, post processing, benefits/limitations, common applications, and new developments focused on “Micro Jetting”. A student will then learn about what is Volume. Unit 6: Binder Jetting In this unit, a student will learn aspects of the Binder Jetting printing process, including working with sand and metal, printer characteristics, materials, dimensional accuracy, post processing, benefits/limitations and common applications, as well as learning how Mass and Space work together in BJ printing. Unit 7: Powder Bed Fusion (Metals) – DMLS/SLM/EBM In this unit, a student will learn the aspects of Powder Bed Fusion (PBF) printing and characteristics of the Electric Beam Melting (EBM) process. Regarding the PBF, the unit covers printer characteristics, dimensional accuracy, post processing, benefits/limitations, and common applications. In addition, the differences between Metal Powder Bed Fusion and Binder Jetting, as well as the aspects of Texture. Unit 8: Decision Making Tools and General Design Considerations for 3D Printing In this unit, a student will learn about decision making tools and general design considerations for 3D printing, including the purpose of and how to use a Technology Summary Table, how to use the Decision Tree to help select the right 3D printing technology, how layer height relates to the printing time, cost, six measurements that can impact a print, and four techniques for making a FFF printer stronger. The unit covers the benefits of Fillets as part of a 3D model, and identifying the aspect of Color as it pertains to a 3D design. Unit 9: Description of 3D Printed Features and Designing for FFF In this unit, a student will learn about 3D design features and descriptions for the FFF printing process, including support structures/part orientation, the ABC’s of support, types of support, bridging, anisotropy, types of infill, holes, design table, four strategies of design strength, 3D checklist, 3D modeling software, online sources for 3D files, repairing 3D files, slicing software, how to print a 3D file, and post processing steps, as well as various aspects of Unity and Variety. Unit 10: Designing for SLA/DLP In this unit, a student will learn the aspects of designing with the Stereolithography (SLA) and Direct Light Processing (DLP) processes, including the support structures/part orientation, the importance of escape holes in hollow sections, a design table providing minimum parameters for printing, basic printer set up, and the operations of SLA slicing software. Including, how to prepare and begin the printing process, wash and cure a print, post processing, troubleshooting, and the aspects of Light as part of a 3D design. Unit 11: Designing for SLS In this unit, a student will learn how to design with using the Selective Laser Sintering (SLS) process, including shrinkage/warping, over sintering, powder removal, moving parts, comparison with Injection Molding, the stepping effect, and referencing a SLS design table, as well as the aspects of Balance in a 3D design. Unit 12: Designing for Material Jetting This unit covers how to design a 3D model when using the Material Jetting (MJ) process. A student will learn how to identify support structures, part orientation, full color printing, multi-integration, and design table, as well as recalling how Time is an aspect of a 3D design. Unit 13: Designing for Binder Jetting This unit covers the Binder Jetting (BJ) process and a student will learn four types of binders, including the aspects of green state, things to consider when creating a design for using the BJ process, color printing, infiltration/sintering, and the tolerances of BJ printing according to the design table, as well as the aspects of Scale. Unit 14: Designing for DMLS/SLM and Design Rules Summary Table In this unit, a student will learn the aspects of Direct Metal Laser Sintering (DMLS) and Selective Laser Sintering (SLS) process, including supports, part orientation, how to orient prints on the DMLS build plate to compensate for hollow sections, skin/cores, common design parameters, constraints based on the metal printing design table, comparing features/descriptions of six 3D printing technologies, and the aspects of Proportion. Unit 15: Tools for Producing 3D Designs This unit covers four types of software used to create a 3D model; CAD Design, Solid Modeling, Surface Modeling, and Sculpting. In addition, CAD Software Variations, Topology Optimization, Reverse Engineering, how to create a 3D form with Scanning, two methods of Physical Measuring, and the aspects of Emphasis in 3D design. Unit 16: 3D Printing Applications This unit presents the advantages of using the 3D printing applications for all six processes. A student will gain insight regarding the differences of jigs/fixtures and the low-volume production of Fused Filament Fabrication (FFF). Making custom surgical/dental guides and hearing aids with using Stereolithography (SLA) and Direct Light Processing (DLP). The aspects of using Selective Laser Sintering (SLS) with creating parts for a panoramic camera and bicycle accessories. The creation of realistic medical training devices used to train the next generation of doctors when applying the Material Jetting (MJ). The sand casting for production of a legacy part when using the Binder Jetting (BJ). In addition, how Direct Metal Laser Sintering (DMLS) and Selective Laser Metal (SLM) are used in real-world applications, such as consolidating a satellite antenna, as well as the aspects of Repetition and Rhythm in a 3D design. Unit 17: 3D Design Considerations In this unit, a student will learn a variety of 3D design considerations, including online 3D printers, how 3D design is not as easy as it looks, exercising a student’s imagination, defining design, the aspects of shape in reference to how it is both a verb and a noun, applying critical thinking skills, encouraging creativity, setting goals, the design process, ideation, linear and lateral thinking, as well as ways to transform a design to increase its impact. Following this unit students are presented with the Final Review and Exam.

This course does not have any sections.